PAA Dosing System

HMD recently built a PAA dosing system in a containerised unit, which you can see from the photographs included. Peracetic acid (PAA) is widely used as a disinfectant and sterilant in food processing.

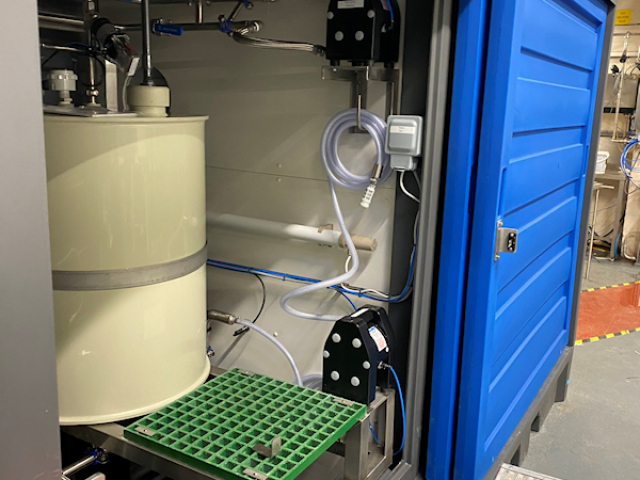

The purpose of this system was to take a neat chemical from an IBC (Intermediate Bulk Container) and pump it into a Plastic 500L tank in a containerised unit.

As this is a system dealing with a neat chemical, it is important that several safety controls are put in place such as pressure relief valves to prevent the PAA vapor from pressure build up inside the pipework. The tank is vented with no additional manway and is sat above a bunded unit. The chemical is then pumped out to the relevant zones where needed.

The unit is split into two sections. One section is electronically interlocked in order to prevent unauthorised access. The other section contains the IBC unit. This has to be changed periodically when emptied and so we made it accessible.

To avoid PAA vapor affecting this area and the external area around the unit, we vented the vapor by pushing it into a scrubber chimney which was fitted with a nozzle. A fine mist is sprayed through the nozzle down the chimney as the vapor rises. This allows the water to absorb the vapor and can then be drained.

All instruments inside the unit are built to be chemically resistant. The system is automated with the only manual operation being the changeover of IBC’s. These systems are very popular as they provide control measures for PAA dosing in a safe environment with very little manual input.